Telecommunication Business

Telecommunications and broadcasting networks form the foundation of the information society. DKK provides support with cutting edge technology and abundant experience.

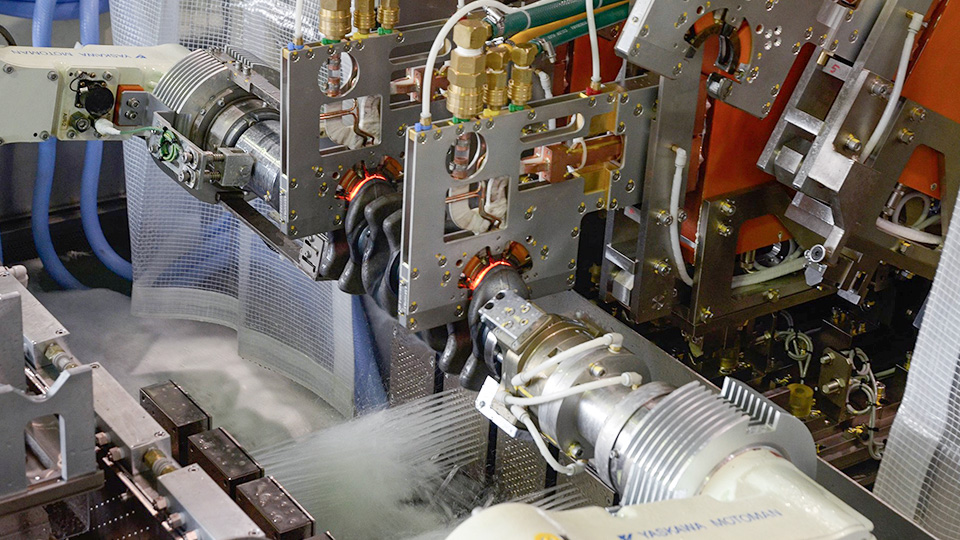

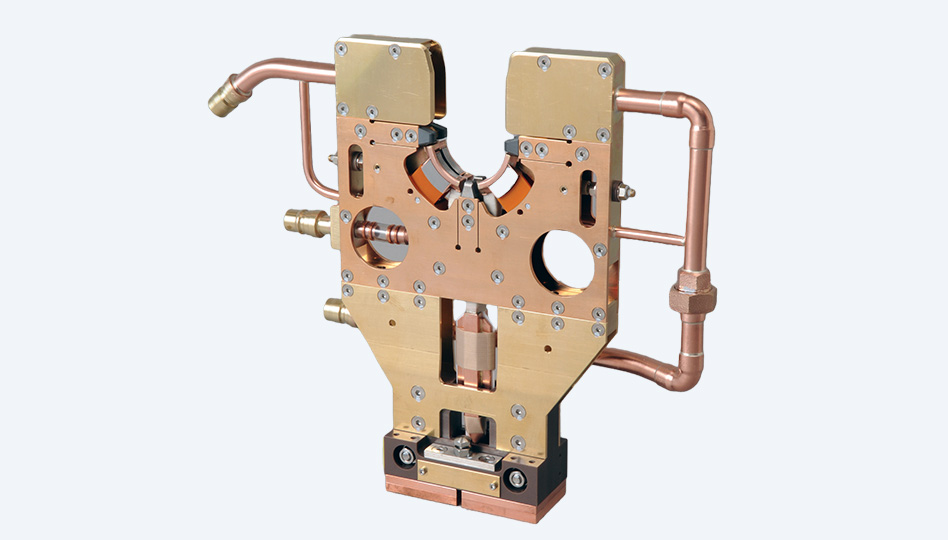

Induction Heating Business

DKK’s clean and efficient induction heating energy is used widely in industry, especially in the automobile industry.

News Release

View All News ReleaseIR News

View All IR News

Sustainability

We are promoting group-wide efforts to realize a sustainable society.